Welcome to our Blog

How To Identify Quality Motor Oil Learn about standards When choosing oil for your vehicle, you should always look or ask for API-licensed oil. API has made it easy to find these oils: licensed oils display one or both of the API motor oil quality marks—the API Service Symbol "Donut" and the Certification Mark "Starburst." These marks are part of API's Engine Oil Licensing and Certification System (EOLCS), a voluntary licensing and certification program that authorizes engine oil marketers meeting API requirements to display the API quality marks. API Service Symbol ''Donut'' See image below The API "Donut" identifies oils that meet current API engine oil standards. It includes the SAE viscosity grade of the oil, API standards met by the oil, and other important performance parameters. The top of the "Donut" displays the motor oil's API performance standard. The letter "S" followed by another letter (API SP) refers to oil suitable for gasoline engines, and the letter "C" followed by another letter and number (API CK-4) refers to oil suitable for diesel engines. The center of the "Donut" shows the motor oil's SAE viscosity grade. Viscosity is the measure of an oil's ability to flow at certain temperatures. The bottom of the "Donut" tells whether the motor oil has resource-conserving properties when compared with a reference oil in an engine test. Motor oils labeled as "Resource Conserving" have passed this test. API Certification Mark ''Starburst'' See image below The API "Starburst" signifies oils which meet the latest International Lubricant Specification Advisory Committee (ILSAC) standard, currently designated ILSAC GF-6A. The ILSAC standards are developed by vehicle and engine manufacturers, oil and additive companies and industry trade associations such as API, ACC, ASTM and SAE. These oils provide engine protection while also delivering improved fuel economy and emission system protection. API Certification Mark ''Shield'' See image below The API "Shield" signifies oils which meet the current ILSAC GF-6B engine protection standard and fuel economy requirements of the International Lubricant Specification Advisory Committee (ILSAC). Note: This mark can only be applied to oils having a viscosity grade of 0W-16. To learn more about API's EOLCS program and quality marks visit API's website.

Here are 10 questions that a buyer of a waste oil furnace should ask themselves: 1. What is the size of the furnace I need? 2. What is the efficiency of the furnace? 3. Do I generate enough waste oil and if I need to supplement what is the costs for waste oil? 4. What is the maintenance schedule for the furnace? 5. Is this furnace built with quality components and what is the warranty on the furnace? 6. What are the installation costs and considerations? 7. What are the noise levels of the furnace? 8. What are the emissions from the furnace? 9. What are the safety features of the furnace? 10. What are the aesthetic features of the furnace? It is important to ask these questions in order to find the best waste oil furnace for your needs. By considering all of these factors, you can be sure to find a furnace that will heat your facility efficiently and affordably saving you money for many years. Here are some additional tips for buying a waste oil furnace: Get a quality quotes from your supplier. Read reviews of different models before making a decision. Make sure the furnace is UL and EPA-certified. Choose a furnace that is the right size for your facility. Consider the efficiency of the furnace when making your decision. Make sure the furnace has a warranty and a dealer who will service the unit. Have the furnace installed by a qualified professional. Ask for references of current customers. By following these tips, you can be sure to find the best waste oil furnace for your needs. Call us today we will be happy to discuss your options.

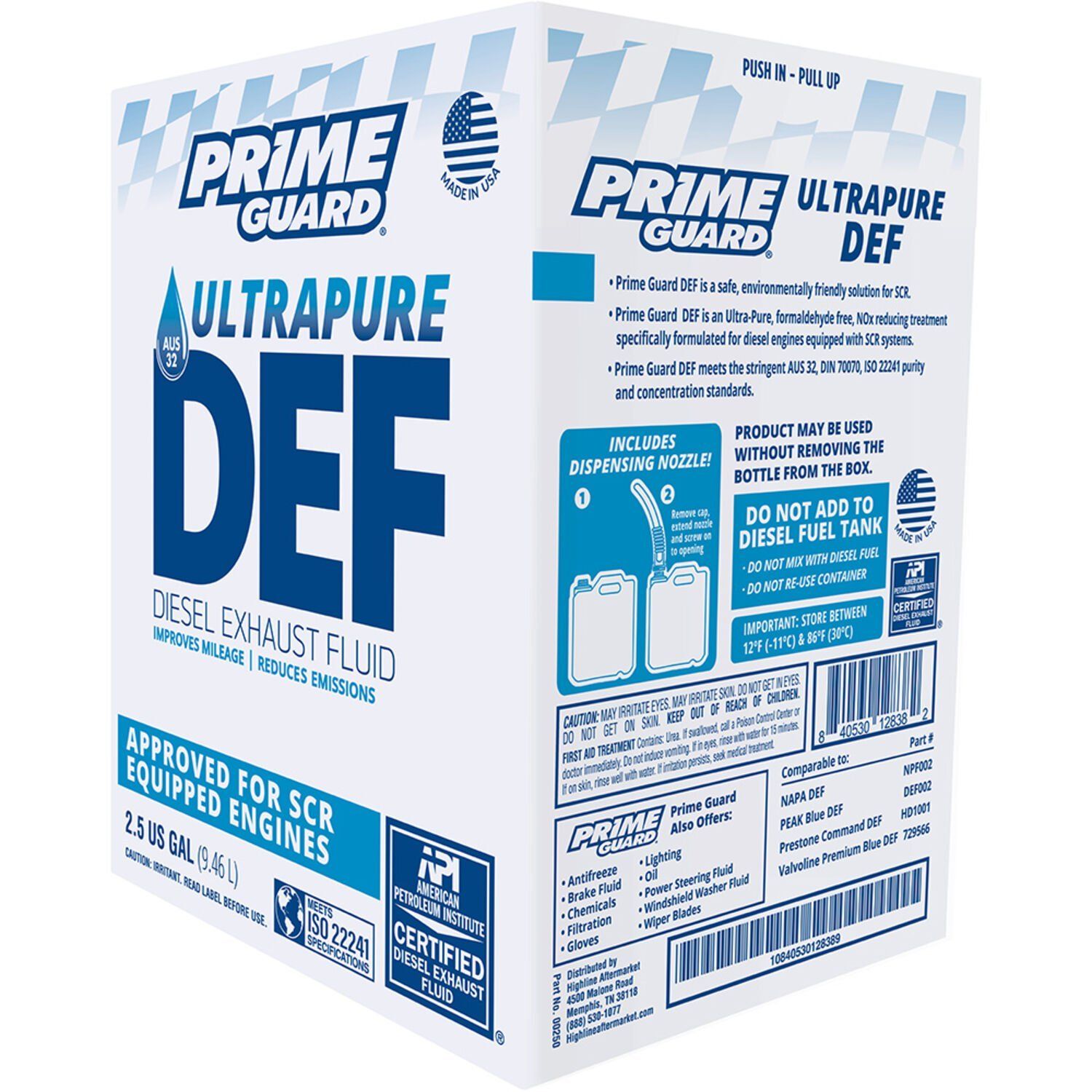

Diesel Exhaust Fluid Facts: Diesel Exhaust Fluid (DEF) started being used in 2010, when the US Environmental Protection Agency (EPA) set new emission-control standards for medium and heavy-duty vehicles. Manufacturers had to devise a new exhaust control system called SCR (Selective Catalytic Reduction) that reduced oxides of nitrogen (NOx), and used a non-hazardous solution called DEF, which is made up of 32.5% urea and 67.5% de-ionized or distilled water. DEF is NOT a fuel additive. It never comes in contact with the diesel itself. It is stored in a separate tank and can be identified by the blue filler cap marked DEF, and is sprayed into the exhaust stream of diesel vehicles to break down dangerous NOx emissions into harmless nitrogen and water. # 1: How Long Can Diesel Exhaust Fluid Be Stored? The fluid contains no preservatives and therefore cannot be stored for longer than 12 months. This is why small fleets should carefully gauge their Diesel Exhaust Fluid usage. Having DEF in store for more than a year can render it unusable in the future. # 2: What Is The Best Way To Store DEF? DEF is corrosive when it comes in contact with aluminum. Store the fluid in ISO-approved containers made from stainless steel, polypropylene or high-density polyethylene. In order to make sure the fluid does not get contaminated, don’t re-use DEF containers. Also, to protect its efficacy, do not pour DEF into some other container. # 3: What Can Happen If DEF Goes Bad? Bad DEF can potentially cause damage to components, including engine de-rating or shutdown. The effectiveness of the fluid can be lost, which means you run the risk of going over the legal limits of your NOx emissions. Problems arising from bad DEF can also invalidate any warranty claims relating to your vehicle’s SCR exhaust injection system or catalyst. # 4: How To Know If Diesel Exhaust Fluid Has Gone Bad? If the clear liquid seems tinted, cloudy, or has some granularity in it, then the DEF you have in store has gone bad. Dispose of it in an ethical manner. # 5: How To Buy DEF On The Road? When on the road, it is often difficult to know if you’re buying DEF that is licensed by API’s Diesel Exhaust Fluid Certification Program. In the absence of brand assurance, look for the expiration date on the container. # 6: How To Buy DEF For Shop Use? Always confirm that your DEF supplier is meeting the ISO quality standard and supplying a Certificate of Analysis with every shipment. Only use API-recognized suppliers # 7: Does Freezing Affect DEF? No. Since it is 2/3 water, it will freeze in colder climates, but that will not affect its performance once it is thawed and made ready for use. # 8: Does Heat Affect Diesel Exhaust Fluid? DEF is best stored at a temperature of about 50 degrees Fahrenheit. Direct sunlight harms the fluid, so store it indoors or in cool, shaded areas. # 9: Does DEF evaporate? Because of its water content, DEF evaporates if stored at higher temperatures for a prolonged period of time. # 10: How To Dispense DEF? Do not use a funnel, pitcher or some other external device to pour Diesel Exhaust Fluid as you will risk contamination. Only pour the fluid directly into the designated DEF tank using the nozzle provided on the storage container. # 11: Does Handling Diesel Exhaust Fluid Involve Taking Safety Measures? DEF is a not-toxic, non-flammable fluid. But it’s a chemical compound nonetheless and protecting your eyes and hands is always a good idea. In the event of spillage, DEF is easy to clean up with ordinary detergent and water. # 12: What is the difference between agricultural urea and the urea used in DEF? DEF uses automotive-grade urea which is far more pure than fertilizer urea. ISO 2224 is the standard that gives recommendations and requirements for handling, transportation and storing Diesel Exhaust Fluid

The Right—and Wrong—Way to Dispose of Your Waste Oil Not only is it unethical and environmentally unsafe to dispose of used oil improperly, but it’s also illegal! Cradle-to-grave laws are in place to enforce safe disposal of waste oil. So, if your company hires a transporter to haul waste oil from your business, you may be held responsible if that transporter violates the laws and standards for disposing of the used oil. Scary, right? Indeed, it is…and it could cost your business major penalties. So, how can you take control of disposing of waste oil without breaking the bank? Convert to waste oil heating. Legal and Financial Benefits of Recycling Waste Oil A waste oil furnace allows you to recycle your used oil products, allowing you to keep the environment safe and stay compliant with the EPA’s rules. Two of the main environmental benefits of recycling your used oil include: Prevent the polluting of soil and water. Re-use a valuable resource (motor oil and other fluids gets dirty, but they don’t wear out). Rather than needing to haul your waste oil off-site and risk spills or other mishaps, you can instead recycle it (by burning it) in your waste oil furnace, producing free heat for your building in the process. So, with a Clean Energy Heating Systems waste oil furnace, you gain the advantages of peace of mind and cost savings. You won’t have to wonder whether your used oil is being handled and disposed of properly. You eliminate the expense of paying someone else to remove and get rid of your used oil. You won’t have to worry about getting fined for a used oil transporter’s lack of compliance. You transform your waste oil into free heat for your facility, saving money on your heating costs year-in and year-out. Get It Right! Want to learn more about how waste oil heating can give you peace of mind and boost your business’ bottom line? Contact us today@ 717 843-9957!

SAFETY TIPS TO PROPERLY INSTALL YOUR WASTE OIL FURNACE’S CHIMNEY COMPONENTS Most businesses that install a waste oil furnace are looking to save money on heating bills while disposing of the waste oil they generate. While you might want to focus on the energy saving and eco-friendly benefits of switching to waste oil heating, you should make sure safety is a top priority when you’re ready to install your waste oil furnace’s chimney components. Our Clean Energy Heating Systems Owner’s Manual provides valuable safety information and tips about installing chimney components. This handy reference guide includes specific instructions and requirements for optimal safety and performance of your waste oil furnace. When you’re ready to install your Clean Energy furnace’s chimney components, be sure to heed these requirements and safety precautions: Use “Class A” insulated stack when making a penetration through the roof or side wall of your building to avoid creating a fire hazard. For best results use stainless steel jacketed stack components. Install proper flashing around the exterior penetration of the stack to make a watertight seal. Use a attic insulated shield around stack that goes through the ceiling. Use only a “Class A” non-restrictive stack cap. The CE-140, CE-180, and CE-250 furnace models require 6” I.D. stack components. The CE-330 and CE-440 furnace models require 8” I.D. stack components. Make sure you have a vertical chimney of at least 10 feet. Keep horizontal runs short and slope horizontal sections at no less than 1/4” per foot rise. Keep the stack installation simple. If you have multiple turns and horizontal runs, you will reduce the natural draft of the furnace. This could damage critical burner components. Install a barometric damper to monitor and adjust draft. Do you have an exhaust fan in your building? If so, make sure adequate make-up air is available. Otherwise, it will create a vacuum in your building and cause a back draft at the furnace, which will damage critical burner components. MAXIMIZE PERFORMANCE AND ROI By installing and maintaining your waste oil furnace and chimney components properly, you will help maximize its performance and ensure that it gives you the biggest return on your investment. Call us today (717) 843-9957 if you have questions about setting up or maintaining your Clean Energy Heating Systems equipment.

Buying A Waste Oil Furnace Items to Consider When Purchasing a Waste Oil Furnace Installation Location Every building presents its own logistical challenges, so it’s important to give this careful consideration when you’re trying to determine the location for your waste oil furnace. And in fact, there are three components you’ll need to plan for: a tank, a chimney stack, and the furnace itself. Read on to learn more about these individual considerations. Tank Location With so many possibilities, choosing a location for your oil tank also demands some time. You could position it outside your building, inside your building or you use our Waste Oil Heating Center. By using our Waste Oil Heating Center, you can actually simplify the thought process, because it keeps all the waste oil heating elements in one convenient place. Chimney Location Several variables specific to your facility will determine where the chimney must be placed. Consult local building codes to see what requirements they have for where the chimney should go and what type of chimney you need to use. Be sure to keep your chimney stack installation simple. If you have multiple turns and horizontal runs, you’ll reduce the natural draft of the furnace, risking damage to critical burner components. Furnace Location Our furnaces can accommodate nearly any shop size and are versatile enough to be mounted to your ceiling, wall or floor mounted on our Heating Center tank or stand. For the ultimate in space-efficiency, our tank and furnace are self-contained in a single unit, so you don’t have to give up a significant amount of valuable floor space. At Clean Energy Heating Systems, our Waste Oil Heating Center includes a 250 or 500 gallon tank and a heavy-duty mount that places the furnace over top of the tank. This is a great solution when space is limited. But even when space is not limited, think about the best location for your furnace. And choose a spot with easy access for clean-outs and service, as well as easy connection to your tank and chimney. Heat Discharge We make our waste oil furnaces with vent ports in multiple locations, so you can install them however it works best for your building’s layout. By choosing a waste oil furnace that has an adaptable output, you can decide how to best heat your facility with it. You can either blow the heat that it generates directly into an open space, or you can channel it into duct-work to vent the heat to specific areas of your building. Our waste oil furnaces can be configured for left, right or even bottom output to maximize installation flexibility. But think about where you’ll need your heat, and how to get the hot air where you need it! This consideration can greatly impact where you locate your furnace. Timing of Installation The best time to install a waste oil furnace is when you don’t need it, because installations take time and sometimes turn into a little bit of a construction project. Installing your waste oil heater in the spring or summer will ensure that your system is up and running when the colder months hit and you need the furnace to heat your facility. This also will allow you to start saving up your used oil now so you have plenty to power your waste oil furnace when winter comes. Ready to Invest in a Waste Oil Furnace? Call today to learn more about the benefits and potential savings your business can gain by switching to waste oil heating. No matter the size of your shop or the volume of used oil you produce, we have a waste oil furnace that’s perfect for your situation.

Three Signs that a Waste Oil Heater Is Right for Your Business As an environmentally friendly and cost-reducing way to heat business facilities, waste oil heaters have a lot going for them. But how can you tell if it’s the right option for your company? While there are many factors to consider, there are some key indicators that can help you identify if you should look more closely at converting to waste oil heating. Three Signs that Your Company Should Seriously Consider a Waste Oil Heater (1) You generate a good supply of waste oil in the course of doing business. If you run a trucking company, car wash, auto repair shop, agricultural operation, or a business that maintains its own fleet of vehicles, you are a prime candidate for using a waste oil furnace! Through oil changes, changing transmission fluid, etc., you produce used petroleum products that can be transformed into free heat for your facility. Even if you don’t produce enough used oil to generate all of the heat you need, you can dramatically lower your energy costs. (2) You want to minimize the risk of non-compliance with government requirements for the safe disposal of waste oil. The cradle-to-grave responsibility for the safe handling of your used oil is no joke! If your waste oil disposal method fails to meet EPA regulations or if there are mishaps—even if a third party messes up when disposing of your used oil for you—your company might be held liable. With waste oil heating, you get control over the removal of your waste oil. With an EPA-approved tank and waste oil furnace, you can store and dispose of your used oil safely and compliantly. That peace of mind will help you sleep better at night! (3) You care about your business’s bottom line. Saving money by using your used oil as free heat for your facility helps cut your company’s expenses, and that has the potential to dramatically boost your profit. Use our online ROI calculator to estimate the savings your business might expect. Then imagine how you might use those dollars to grow your business, as you reinvest them into your company. Let’s Talk! call today 717 843-9957 If the three signs above describe you, contact us to discuss your facility’s heating needs. We are here to help you assess the viability of waste oil heating for your business and to explain the innovative features that make Clean Energy Heating Systems waste oil furnaces a cut above others on the market.

A barrel of crude is 42 gallons. After processing the volume increases to about 45 gallons this is called processing gains. The increase is from separating out the lighter products which has a lower specific gravity than the crude. The main product is gasoline at around 45% followed by Diesel fuel and heating oil at 25%, kerosene and jet fuel account for 9%. Other Product made from the remaining crude include residual fuels, plastics, propane, natural gas, synthetic rubber, waxes, asphalts, pharmaceuticals, cosmetics, paints and solvents. So how much lubricant is in a barrel? Less than .05% or about one quart.